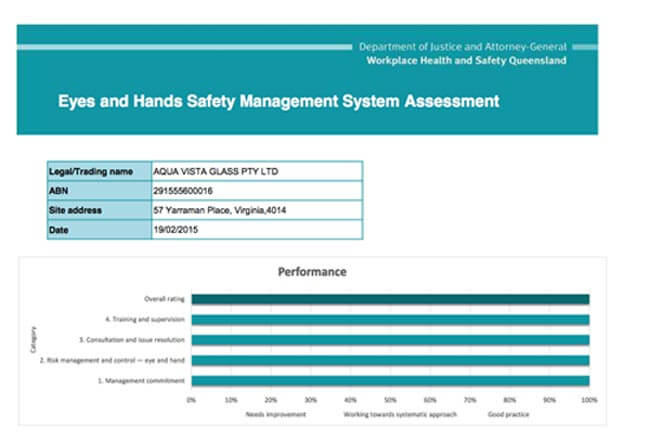

We just completed our annual workplace safety audit, and we got a perfect score. This is very rare in the industry, almost unheard of, in fact. We received 60 out of 60 points, and are extremely proud of it.

The audit consists of 20 evaluation questions designed to assess the degree of workplace safety a business is practicing. Ratings for each question range from 0 (meaning the company doesn’t engage in that particular safety practice at all), to 3 (which means the workplace always engages in that particular safety practice). The audit is administered by the Department of Justice and Attorney-General Workplace Health and Safety Queensland.

We scored a 3 (always engages in that particular safety practice) on all 20 questions. These questions included:

- Does management demonstrate commitment to health and safety in the workplace? – Yes, with a monthly safety meeting, a WHS policy that is displayed and up to date, documented safe work procedures, and a return to work coordinator for all employees.

- Are health and safety responsibilities specifically allocated in the workplace? – Yes. Safety responsibilities are outlined in most job descriptions. Our management is active in the workplace and easily accessible by workers who have questions about their responsibilities in these areas.

- Are safety issues identified and actioned? – Yes

- Is safety considered when purchasing items? – Yes

- Is safety considered when designing/changing work processes? – Yes

- Do managers lead by example in relation to safety? – Yes

- How are risks identified? – We were commended for having documented procedures for hazard identification and risk assessment.

- Are risk assessments conducted? – Yes

- What controls are in place for managing risk? – We were commended for having photos of our PPE signage)

- How are safe work procedures developed and implemented in the workplace? – We were commended for our quarterly safety newsletter.

- Are safety responsibilities communicated throughout the organisation? – Yes, with pre-start meetings and our documented issue resolution policy.

- Are there mechanisms in place for discussing safety? – We consult employees on PPE for eye and hand.

- Are the safety mechanisms functioning effectively? – Team meetings are held on this topic and documented.

- Are workers given opportunities to participate in safety activities? – Our workers participate in safety audits.

- Are workers able to have input into decisions that affect safety? – Our workers can raise issues in safety meetings, and those issues are taken to management.

- Are workers inducted before they start work? – We have a documented induction program.

- Does the induction program cover relevant health and safety information and issues/risks/hazards? – Yes

- Are employees trained to perform their job safely, including participating in safe work procedures? – Yes

- Is workers’ understanding of training assessed? – Yes

- Do supervisors routinely check whether workers follow safety procedures/established work processes? – We supervise our workers and enforce safety standards.

As you can imagine, the team here at Aqua Vista Glass is extremely proud of our results throughout this stringent workplace safety audit. It reflects the strict standards we impose within our company that is reflected in our outstanding customer service and product quality to you, the customer. If you are looking for the highest quality frameless glass pool fencing and balustrade in the business, contact us at Aqua Vista Glass today!